SIEMENS Mobility South Africa

Siemens Mobility’s Latest Generation

Axle Counters Fit Seamlessly with

Legacy Systems

A key element to safe railway operations lies in ensuring that the section of track the train is running on is not simultaneously occupied by another train. Similarly, this applies to when a train is arriving or departing a station. Not only do axle counters perform this safety critical role, but they also form the basis for rail automation, as well as the broader signalling solution offered by Siemens Mobility (Pty) Ltd.

Axle counters do exactly what their name suggests: count the number of axles of a train by sending a signal from the track side system to an electronic evaluator unit which calculates how many axles have entered into a specific section of the track – and that number needs to match what exits that track section. In other words, a net count of zero.

Latest Technology

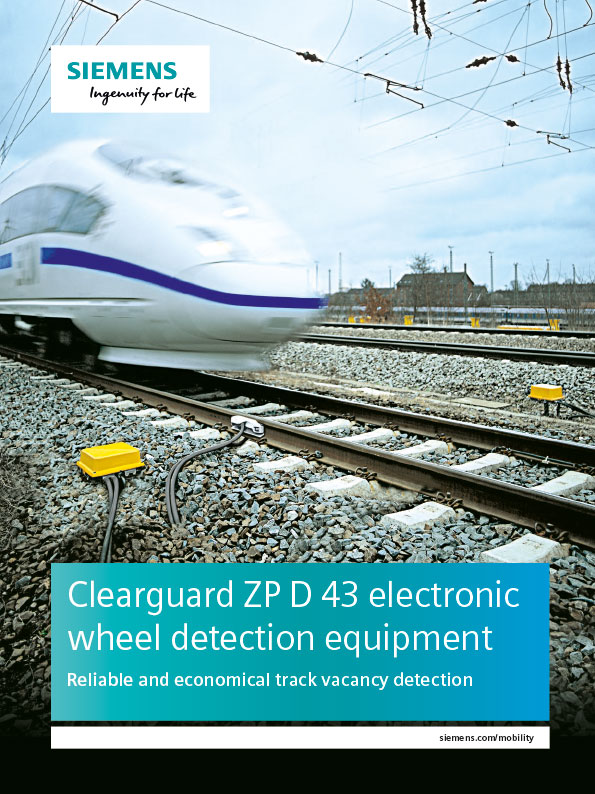

The Clearguard ACM 200 comprises of the Clearguard ZP D 43 electronic wheel detection equipment and the ACM 200 evaluator. The Clearguard ZP D 43 consists of a double wheel detector with the associated connecting cables and a trackside connection box. The double wheel detector is physically installed on the track. Two or more Clearguard ZP D 43 units monitor a track vacancy detection section. When a wheel enters the detection area of the double wheel detector, it changes the strength of the alternating electromagnetic field, thereby generating signal pulses. These pulses are evaluated in the trackside unit, transmitted to the evaluation computer in an ISDN protocol format – within the relay based interlocking or electronic interlocking system.

The axle counting system is CENELEC SIL4 approved and approved by local operators such as Transnet and PRASA.

Magendhren Reddy

Business Development

Siemens Mobility (Pty) Ltd

Clearguard ZP D 43 electronic wheel detection equipment Reliable and economical track vacancy detection

Download full technical brochure.

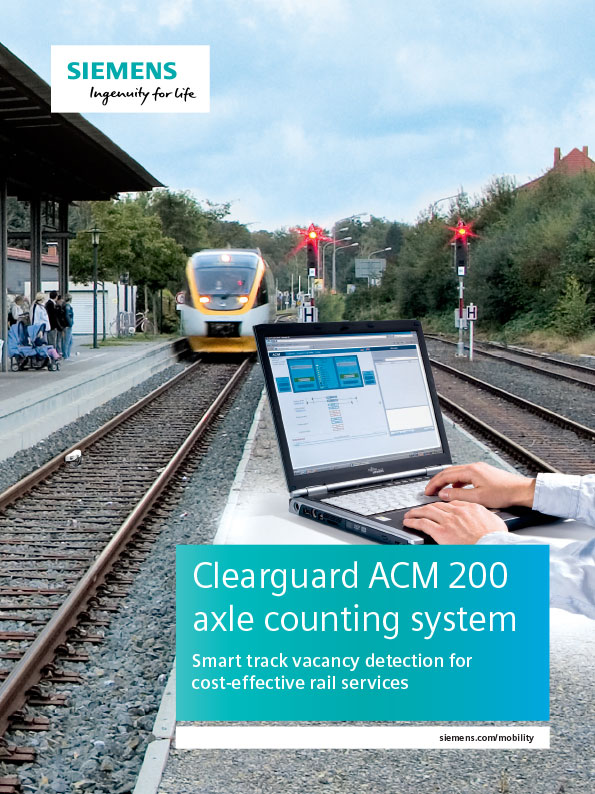

Clearguard ACM 200 axle counting system Smart track vacancy detection for cost-effective rail services

Download full technical brochure.

Phased installation approach to accommodate legacy equipment

“The advantage of the system is its compatibility with legacy systems. This allows operators to phase in the new technology and run a more efficient and safe railway,” notes Magendhren

“These systems can be implemented as part of a green field project or phased-in as upgrades for currently installed legacy Siemens axle counter equipment. The advantage of the latter is that the product for the wheel detection and the ACM 200 evaluator can be interchangeable with the legacy technology. “What this means is that if a customer has a limited budget but is looking towards the future in terms of technology – they can upgrade the wheel detection equipment with the ZP D 43 i.e. replace the legacy ZP 43 V or E track side equipment, that will then communicate with the legacy evaluator systems. Either the AZS 350 U, or the AZ S M (R). Alternatively, the evaluators could be replaced by the ACM 200 evaluator, which would continue to communicate with legacy track side equipment,” explains Magendhren.

The current installed base of Siemens ACM 200 axle counters in South Africa, is around 2,600 units, alongside around 6,000 ZP D 43-wheel units, which is over and above the legacy equipment that Siemens currently has installed on the network.

In Botswana, Siemens Mobility has used the axle counting solution as part of the foundations for a bespoke Level Crossing solution. “The axle counters in this instance detect the approaching train in order to activate the Level Crossing,” explains Magendhren.

From a global perspective the Siemens Mobility axle counting systems are prevalent in over 30 countries with an install base of more than 40,000 units.

Complementing technology support

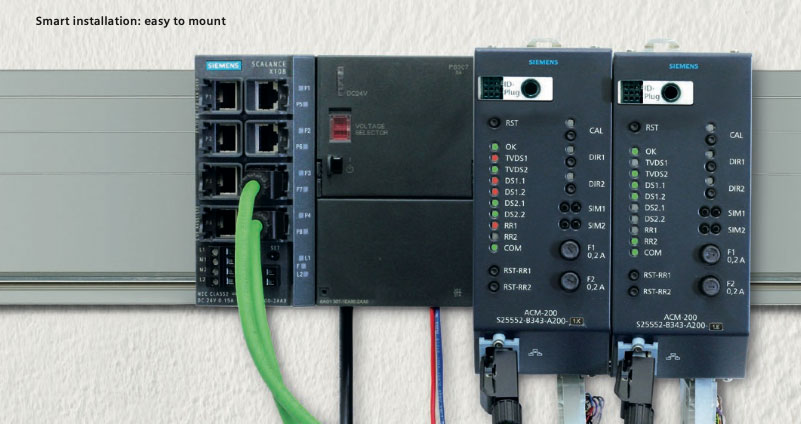

In addition to the axle counting functionality of the ACM 200 axle counter, there is a complementing product which is just as critical and is responsible for the fail-safe data transmission of information from one station to the next. This is the DCM 150, which has the same look and feel as the ACM 200 and is also DIN rail mounted. The DCM 150 allows for the transmission of up to12 vital bits between stations.

To provide additional support to customers, Siemens Mobility has developed an Asset Performance Management solution, which provides an overview of all the ACM 200 assets within an operators network. The system provides both a performance analysis of the units, as well as fault detection and includes a recording functionality for faults and repair history for auditing purposes. The solution can be implemented as a stand-alone system or housed in the cloud.

The following video was created pre-COVID.

Dealing with vandalism

“In South Africa and more widely across Africa vandalism of track side infrastructure is becoming more prevalent, so we have a developed a few work arounds to deal with this,” notes Magendhren.

Some of the anti-vandalism measures implemented focus on how track vacancy detection equipment is housed: either in double walled silos or in steel junction boxes. Counting heads are protected by rugged resin head protectors. Indoor electronic equipment is housed in concrete enclosures with steel safe doors.

Visit the Siemens Mobility Company page for more information regarding their railway solutions.