SIEMENS Mobility South Africa

The Point of Points Machines

Points machines are an important factor in the safety of rail services and an essential part of controlling the directional change of a train. If points machines do not operate precisely, the network cannot operate safely. But many points on South Africa’s railways are ageing hydraulic machines which are coming to the end of their operational lives and will need to be replaced in the next few years.

Siemens Mobility (Pty) Ltd, provides a range of modern electro-mechanical points machine types that are suitable for all track gauges, freight types and line speeds across the South African rail network. In Southern Africa two main track gauges exist, Standard gauge (1,435mm), found on the Gautrain network, as well as Cape gauge (1, 067mm) which is in relative terms a narrow gauge, found on the remaining major portion of the rail network and used extensively by Transnet and the Passenger Rail Agency of South Africa (PRASA).

How Do Points Machines Work?

“Safe train movement between tracks is fundamentally important. This guided movement is carried out by an operator working on an interlocking system which is electrically connected to a points machine which is installed on the side of the track,” says Deon Naidoo, Country Business Unit Manager Siemens Mobility (Pty) Ltd.

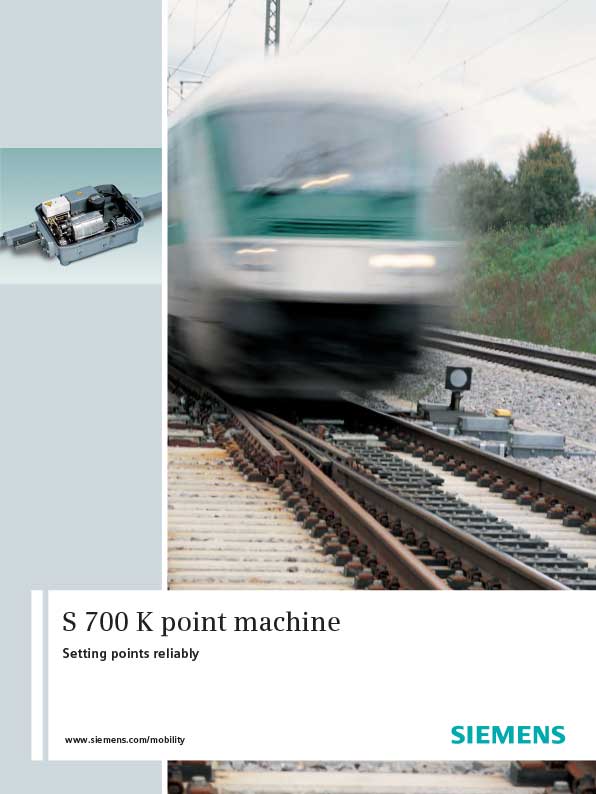

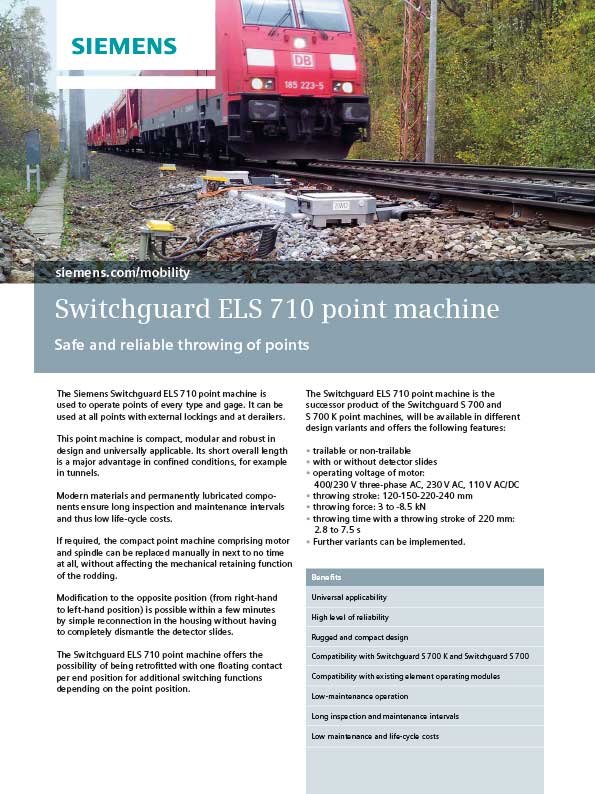

A points machine is located on the side of the track and is physically connected to a turnout by steel rodding. Points machines, also known as a switch machine can be electro-mechanical or hydraulic. Electro-mechanical points machines are designed to move and lock, while retaining continuous control of the position of the turnout. These machines consist of a motor, gears for rotational to linear movement, clutch, detection circuitry or contacts for monitoring stroke completion, hand crank for manual and emergency operation, metal slides which are connected to the turnout using metal rodding and finally a housing and cover.

“Our Siemens Mobility electro-mechanical points machines have been successfully installed in both Standard and Narrow gauge lines, as well as, low speed freight and passenger lines as seen in South Africa. We also have several installations on high speed lines globally,” explains Deon.

The points machine solutions offered by Siemens Mobility can be tailored to keep lifecycle costs as low as possible. Deon notes that, by using one type of points machine for all types of turnouts, including double slips brings significant cost efficiency to the operator.

From Legacy to the Latest Technology

The points machines can be installed in legacy relay interlockings used at Transnet, electronic interlocking such as the Siemens SICAS S7 used at PRASA, as well as, the Siemens new cloud based interlocking solution seen in Austria.

“The Siemens’ points machines can easily replace aging or problematic hydraulic points machine solutions. A further advantage is that the electro-mechanical points machines do not suffer from hydraulic failure or loss of throw force. They can be fitted to small 1:7 turnouts all the way to 1:20, including double slip turnouts. All our machines have been extensively tested, before being brought into operation” explains Deon.

The Siemens points machines have been successfully installed in Safety Integrity Level or SIL 4 electronic interlocking systems and meets all applicable safety criteria.

“The points machines can also be fitted with our vandal proofing system to prevent theft and vandalism, as well as, our diagnostics system to determine possible failure before it happens as part of our predictive maintenance system.”

Mobile monitoring is made available for operators via an app on both Android and iOS platforms, alerting customers of any points machine issues, so technicians can be quickly dispatched to repair the fault.

Sales and Service Support

Siemens provides all spare parts, together with full after sales support ranging from small repairs on site, to major overhauls of the points machines, to ensure that the customer has high availability. Support services can be seamlessly integrated into the customers operations with full tailoring, including support packages to suit the customer’s budget and operational requirements.

“We provide reliable solutions and give our customers the comfort of knowing that the Siemens points machines have been operating in excess of 40 years in some parts of the world and for more than 30 years here in South Africa. We pride ourselves in saying that our customers capital investment is protected by a strong brand, reliable product and a highly skilled local support team,” concludes Deon.

Visit the Siemens Mobility Company page for more information regarding their railway solutions.